Living With the Problems of Limescale

Limescale is one of the leading causes of inefficiency and premature failure in hot water cylinders, particularly in hard water areas.

For homeowners, it means higher energy bills, unreliable hot water, and unexpected repair costs. For installers and engineers, it remains one of the most common root causes of immersion heater failures, overheating incidents, and customer call-backs.

At Cotherm, we work closely with manufacturers, installers, and system designers to deliver reliable thermal control solutions.

This Guide Explains:

- What causes limescale in hot water cylinders

- How limescale affects immersion heaters

- How to recognise early warning signs

- The most effective ways to prevent and control scale buildup

⚡

Electrical Safety Warning

For safety reasons, it is always advised to use a

fully certified and fully insured professional

for any work involving electricity, heating elements, or hot water systems.

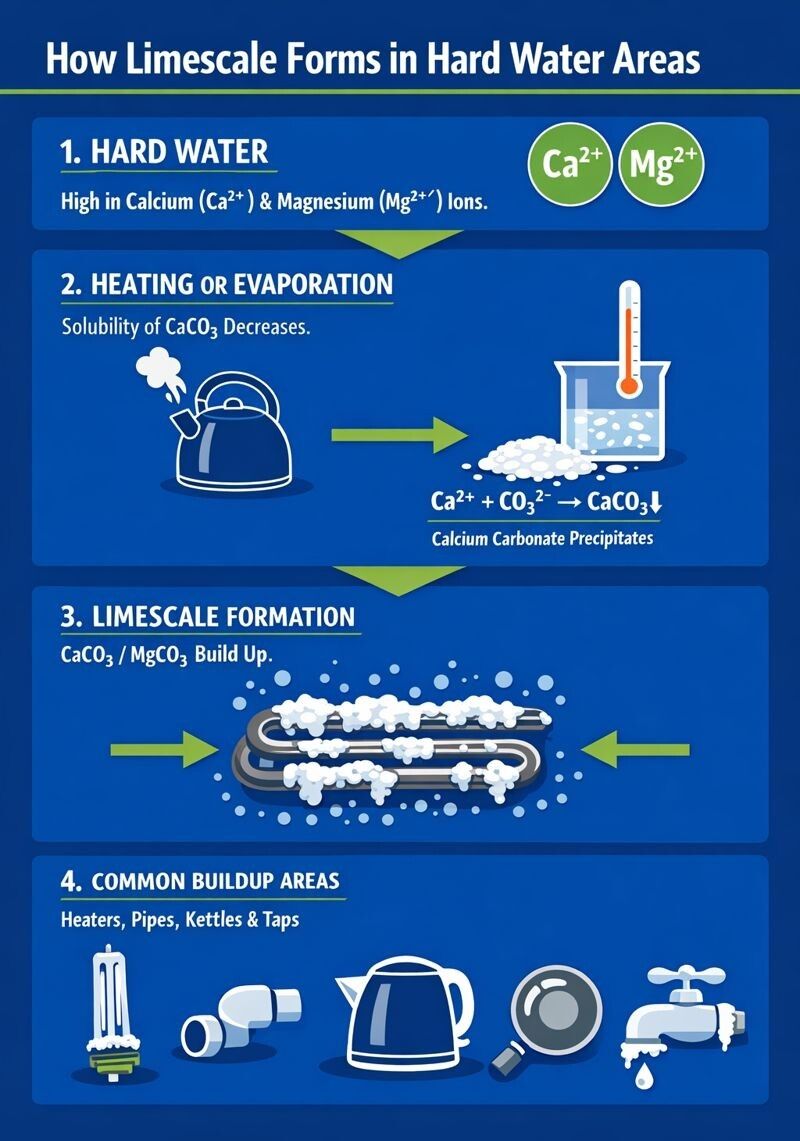

What is Limescale and Why Does it Form on Immersion Elements?

Limescale is primarily made of calcium carbonate, a mineral deposit created when hard water is heated.

Hard Water and Dissolved Minerals

In hard water areas, mains water contains high levels of dissolved calcium and magnesium bicarbonates. These minerals are:

- Invisible in cold water

- Naturally occurring

- More concentrated in borehole, spring, and well supplies

How Heat Triggers Limescale Formation

When water is heated inside a hot water cylinder:

- Calcium bicarbonate becomes chemically unstable

- It breaks down into calcium carbonate and carbon dioxide

- Calcium carbonate forms solid deposits (limescale)

- These deposits attach to hot surfaces

Once formed, calcium carbonate does not re-dissolve into water. Instead, it accumulates on:

- Immersion heater elements

- Cylinder walls

- Heat exchanger surfaces

- The bottom of the tank as sludge

Why Immersion Elements Attract Limescale

Immersion elements are the hottest components in a cylinder. High temperatures cause:

- Faster mineral separation

- Micro-boiling at the element surface

- Accelerated scale adhesion

With every heating cycle, more scale forms. Over time, thick layers develop, reducing heat transfer and system efficiency.

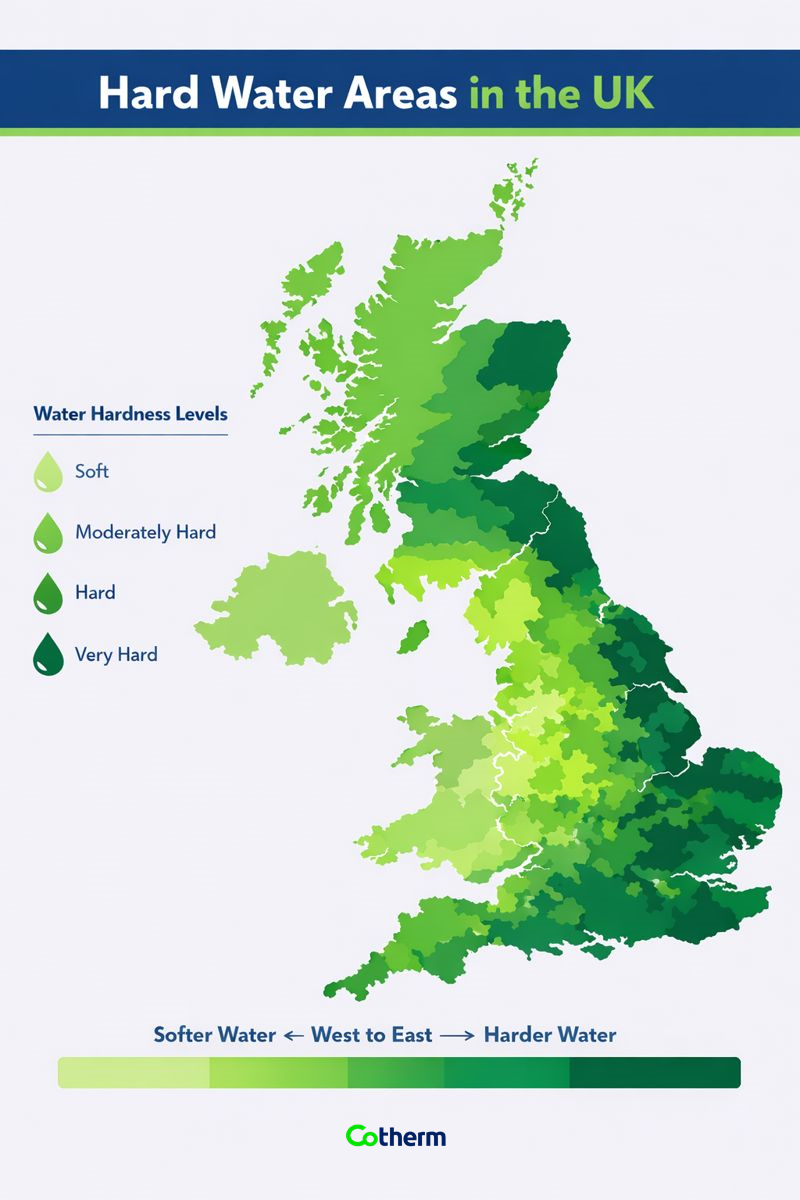

UK Hard and Soft Water Areas and Their Impact on Immersion Heaters Lifespan

Water hardness varies significantly across the UK and plays a major role in limescale formation and immersion element reliability.

In general:

- Soft water areas include Western Scotland, Wales, Northern Ireland, and the North West.

- Hard and very hard water areas include London, the South East, East Anglia, and parts of the Midlands.

These regional differences are caused by local geology. Water flowing through chalk and limestone absorbs higher levels of calcium and magnesium, making it harder.

In hard water areas, these minerals form limescale more quickly when heated. This leads to faster insulation of heating elements, higher operating temperatures, increased thermal stress, and a greater risk of burnout.

As a result, immersion heaters in hard water regions typically experience

higher failure rates and shorter service life compared to systems in soft water areas, where limescale formation is minimal.

Understanding local water hardness is therefore essential when selecting components and planning maintenance to maximise system performance

and longevity.

How Limescale Affects Immersion Elements and Hot Water Systems:

1. Reduced Heat Transfer and Insulation

Limescale acts as an insulating layer. Because calcium carbonate is a poor conductor of heat:

- Heat cannot transfer efficiently into the water

- The element must operate at higher temperatures

- Energy consumption increases

2. Overheating and Thermal Stress

As heat becomes trapped beneath scale:

- Element temperatures rise above design limits

- Internal resistance wires experience thermal fatigue

- Core insulation materials degrade

This significantly shortens the life of immersion heaters.

3. Accelerated Component Failure

Prolonged overheating can cause:

- Burnout of resistance coils

- Cracking of outer sheaths

- Insulation breakdown

- Activation of safety cut-outs

This is why immersion elements in hard water areas often fail prematurely.

4. Higher Energy Bills and Slower Heating

Limescale forces the system to work harder to achieve the same water temperature:

- Longer heat-up times

- Increased electricity consumption

- Reduced overall efficiency

Even moderate scale buildup can raise energy costs by a substantial margin.

5. Hot Spots and Localised Damage

Limescale does not form evenly. Thick patches create hot spots where:

- Temperatures exceed safe operating limits

- Pinholes can develop in the element sheath

- Water enters and rapidly turns to steam

Because steam expands up to 1,700 times the volume of water, this process can cause sudden element rupture.

📌Hot spots caused by uneven limescale build-up are widely regarded as the most common and most destructive failure mechanism in immersion heating elements, particularly in hard water areas.

6. Secondary System Damage

Detached scale particles may:

- Settle at the base of the cylinder

- Cover thermostats and sensors

- Interfere with heat exchangers

- Disrupt temperature control

These issues affect system reliability and comfort.

How to Identify Element Limescale Problems in a Hot Water Cylinder

Because most cylinders are sealed systems, internal inspection is difficult. However, several warning signs indicate scale buildup.

Common Symptoms of Limescale

- Longer heating times

Water takes noticeably longer to reach temperature - Higher energy bills

Increased costs without changes in usage - Noises during heating

Crackling, rumbling, or kettling sounds - Hot water running out quickly

Premature thermostat shutdown - Fluctuating water temperature

Uneven heating and poor stratification - Repeated element failures

Frequent burnout or safety cut-out activation - Visible scale during maintenance

Chalky white deposits on elements - Cloudy or discoloured hot water

Suspended scale particles

📌Early detection helps prevent costly repairs and system downtime.

If you suspect your element may be failing due to scale buildup, our guide on how to test if a hot water cylinder’s immersion element is faulty walks through safe diagnostic checks.

🔗

How to test if a hot water cylinder’s immersion element is faulty

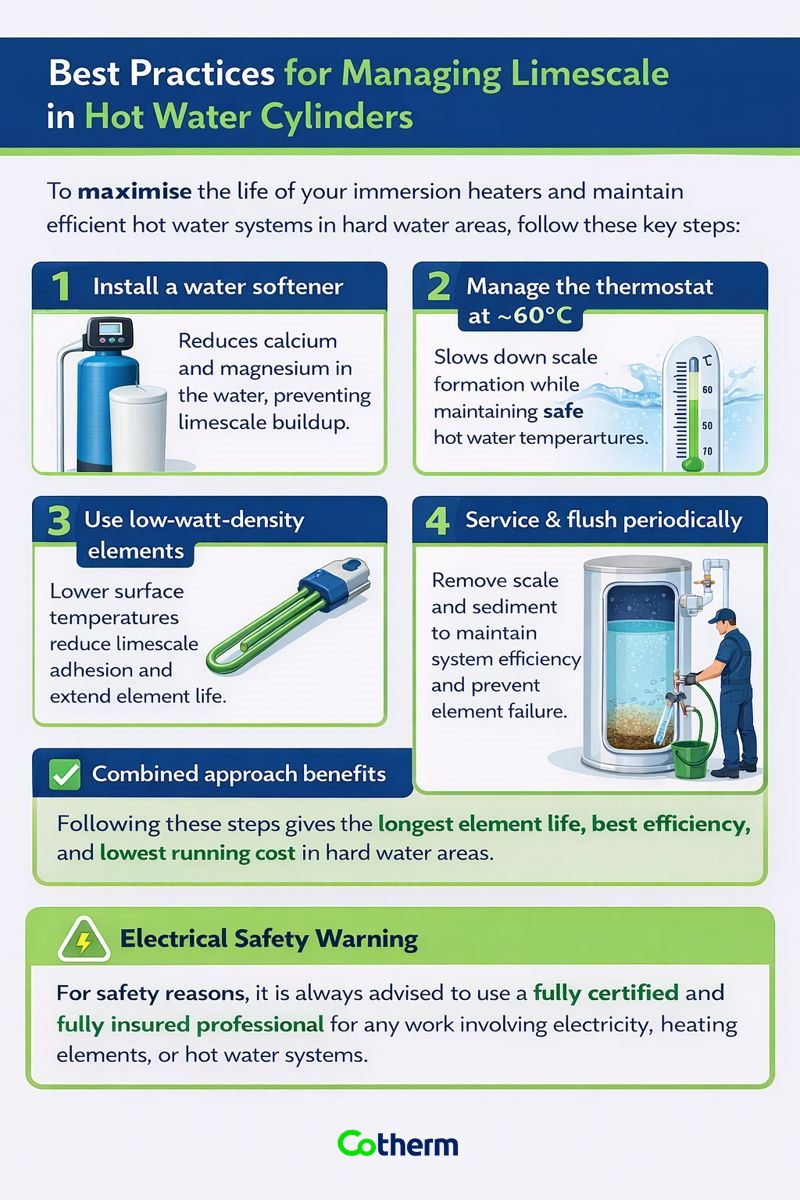

How to Prevent and Control Limescale on Immersion Heater Elements

Effective limescale management requires a combination of prevention, maintenance, and component selection.

1. Install a Water Softener

Ion-exchange water softeners are the most reliable method for preventing limescale.

They work by removing calcium and magnesium ions and replacing them with sodium ions, preventing scale formation before water enters the cylinder.

Benefits of Water Softeners:

- Protects heating elements, cylinders, boilers, and pipework

- Improves heating efficiency

- Extends component lifespan

- Reduces maintenance requirements

- Improves appliance performance

For properties in hard water areas, water softeners provide system-wide protection.

2. Schedule Regular Descaling and Maintenance

Preventative maintenance reduces accumulated scale and debris.

Recommended actions include:

- Full cylinder flushing

- Professional chemical descaling

- Removal of sludge and sediment

- Inspection of heating elements and sensors

Routine servicing maintains optimal performance and reduces failure risk.

3. Optimise Thermostat Settings

Operating temperature strongly influences scale formation.

- Recommended setting: Approximately 60°C

- Lower temperatures slow mineral precipitation

- Avoid temperatures below 60°C to prevent legionella risk

Balanced temperature management improves efficiency and safety.

4. Control Heating Cycles

Avoid unnecessary overheating by:

- Using timed heating schedules

- Preventing continuous operation

- Matching heating cycles to usage patterns

This reduces thermal stress and scale acceleration.

5. Choose Limescale-Resistant Immersion Elements

Material selection plays a critical role in durability. (see table below)

Low Watt Density Elements

Low watt density elements distribute heat over a larger surface area, resulting in:

- Lower surface temperatures

- Reduced scale adhesion

- Longer service life

They are especially effective in hard water environments.

Common Heating Element Materials

Material selection plays a critical role in limescale resistance and durability.

Best Practices for Limescale Management

For maximum system performance and longevity, Cotherm recommends:

- Installing a high-quality water softener

- Maintaining thermostat settings near 60°C

- Using low watt density, corrosion-resistant elements

- Scheduling routine cylinder servicing

- Monitoring energy consumption patterns

Limescale is more than a cosmetic issue, using this integrated approach delivers:

- Higher Energy efficiency

- Reduces environmental impact

- Lowers operating & maintenance costs

- Improves system reliability & reduces breakdowns

- Extends equipment lifespan

📌By managing scale effectively, you protect your investment and ensure consistent hot water performance.

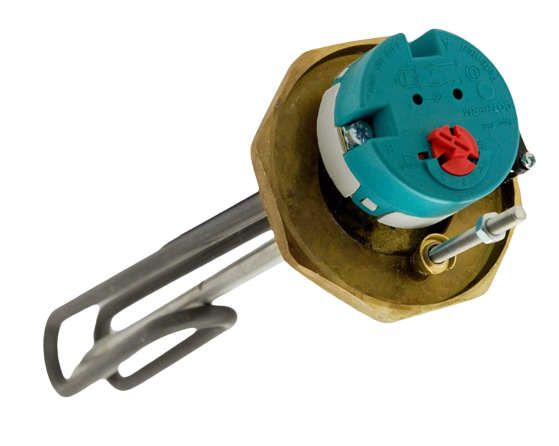

Cotherm: Supporting Reliable Water Heating Systems

At Cotherm, we design and manufacture advanced thermostatic controls, immersion heaters, and thermal safety solutions for domestic and commercial water heating systems.

Our products are engineered to perform reliably—even in challenging hard water conditions—when combined with proper system management.

Explore our technical resources to learn more about optimising your hot water system or contact our team for expert guidance.

Best Practices for Managing Limescale on Immersion Heater Elements

Questions & Expert Answers on Limescale and Immersion Heater Elements

Clear answers from a professional:

What are the main signs of limescale buildup in a hot water cylinder?

Typical signs include:

- Rumbling or kettling noises

- Slow water heating

- Temperature fluctuations

- Frequent element failures

- White chalky deposits on removed elements

These symptoms suggest internal limescale accumulation.

What causes limescale to form on immersion heater elements?

Limescale forms when hard water is heated. Heat turns dissolved calcium and magnesium minerals into solid calcium carbonate, which sticks to hot surfaces inside the cylinder.

Does lowering the thermostat reduce limescale buildup?

Yes. Setting the thermostat to around 60°C slows down limescale formation while maintaining safe hot water temperatures. Higher temperatures accelerate mineral separation.

Can limescale increase my energy bills?

Yes. Limescale reduces heat transfer, meaning the immersion heater must run longer and hotter.

This can significantly increase electricity consumption and running costs.

What is the best way to prevent limescale in a hot water cylinder?

The most effective methods are:

- Installing a water softener

- Using low watt density immersion heaters

- Maintaining correct thermostat settings

- Regular servicing and flushing

This combination provides long-term protection.

Why does my immersion heater keep burning out or tripping the fuse?

Repeated burnout is usually caused by limescale build-up on the heating element.

Limescale insulates the element, traps heat, and causes overheating, which leads to internal damage and electrical failure.

There could be other reasons, so be safe and call a professional.

Can I fix limescale problems myself or should I call a professional?

If you are qualified or competent to carry out the work, you may be able to manage minor limescale build-up through basic cleaning or routine maintenance.

However, persistent or severe limescale should be handled by a qualified engineer. Professional servicing ensures electrical and mechanical safety, protects system components, and helps prevent further damage or premature failure.

⚡ Electrical Safety Warning!

For safety reasons, it is always advised to use a fully certified and fully insured professional for any work involving electricity, heating elements, or hot water systems.